Strain gage selection 101 one of the first steps in selecting a strain gage requires knowing something about the material to which the gage will be bonded.

Micro measurements strain gauge selection.

In general gauge gage with the added u is the most common spelling.

Detailed technical information about the selection and application of strain gages can be found in the special series of tech notes tech tips and instruction bulletins on strain gage technology.

11055 revision 30 may 2018 1 0 introduction the initial step in preparing for any strain gage installation is the selection of the appropriate gage for the task.

However at micro measurements we use the more unique spelling gage to highlight the unique quality of our products.

Micro measurements strain gage selection.

Micro measurements announces successful integration of advanced sensors technology into linear pattern strain gage sensors for industry best in class design and performance characteristics.

Most strain gage types are available in a variety of stc self temperature compensation values which correspond to the coefficient of thermal expansion cte of the substrate material in.

0 031 0 79 mm to 0 250 6 35 mm.

Advanced sensors technology applies tangible specification and manufacturing process improvements along with industry exclusive strain gage sensor design.

Micro measurements strain gages for shear modulus testing.

Dimensions listed for gage length as measured inside the grid endloops and grid width refer to active grid dimensions.

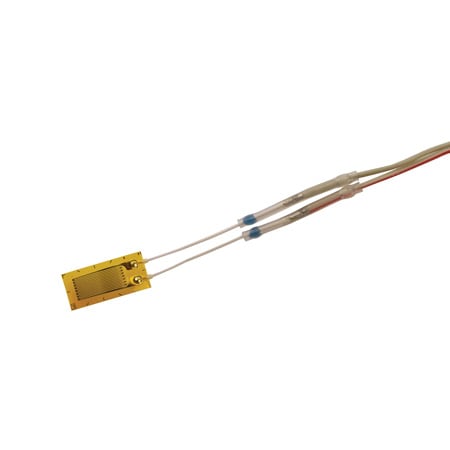

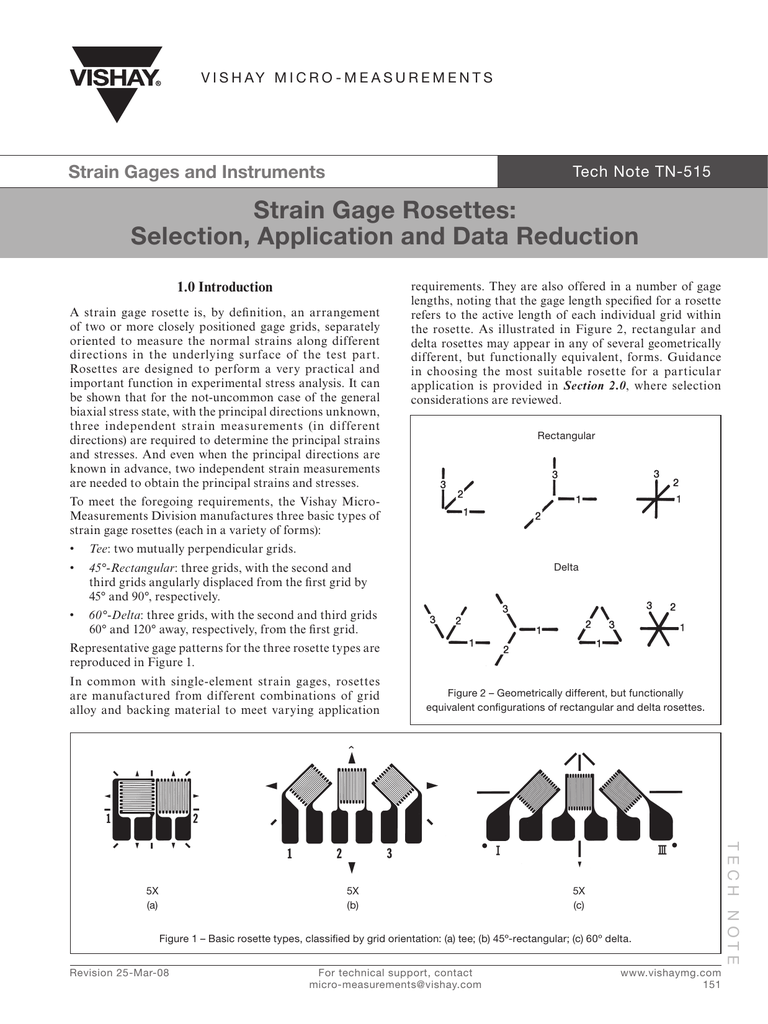

Micro measurements 3 element rosette strain gages are specifically designed for determining principle stresses and strains.

Thorough familiarity with these publications will help ensure consistent success in the use of micro measurements strain gages.

As a noun in today s usage gage and gauge simply refer to an instrument used for measurement as in our strain gages or strain gauges.

They are available in both stacked and planar constructions and in lengths ranging from.

Micro measurements offers a full complement of strain gages gauges photostress equipment and coatings data acquisition systems and gear necessary to obtain accurate reliable stress data.

All patterns have three grids oriented at 0 45 and 90 angles.