The following show 12 6 and 3 2 mm 1 2 1 4 and 10ga mild steel cut with oxygen on a 2kw fiber laser and examples of the same part cut with 1 variable changed to show how it affected the cut quality.

Mitsubishi laser cutting conditions.

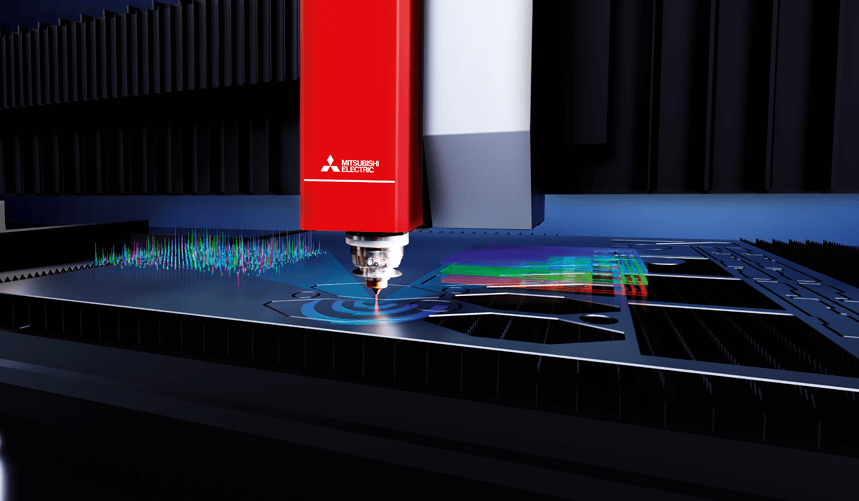

Equipped with mitsubishi electric s sophisticated control drive system and fiber laser oscillator the rx f offers eco friendly laser cutting.

Factory cut chart settings.

It comes standard with an eco mode which switches off components of the laser system in stages when the processing is suspended minimizing power consumption during standby.

Delivers unprecedented performance creating the future of laser processing.

3d laser cutting systems offer the ultimate in accuracy and flexibility for users across a wide range of complex laser applications.

All cutting parameters are set around this including assist gas.

At 100 ipm the assist gas pressure and flow rates are set to evacuate the molten metal cleanly and efficiently.

Say a machine s cutting conditions are set so that the laser cuts at 100 ipm in a certain material producing a 0 010 in wide kerf.

Our vast line up of 2d and 3d laser processing machines offer the ultimate in speed accuracy and flexibility.

When the spot position changes.

Help with cutting parameters jr mfg mechanical 6 nov 16 04 44.

We design and manufacture every critical component that goes into our laser system from the cutting machine to resonator and control unit.

.jpg)